The principle that geomembrane can play the role of anti-seepage is mainly through the waterproof and anti-seepage performance of its material.

How does the geomembrane play an anti-seepage role?

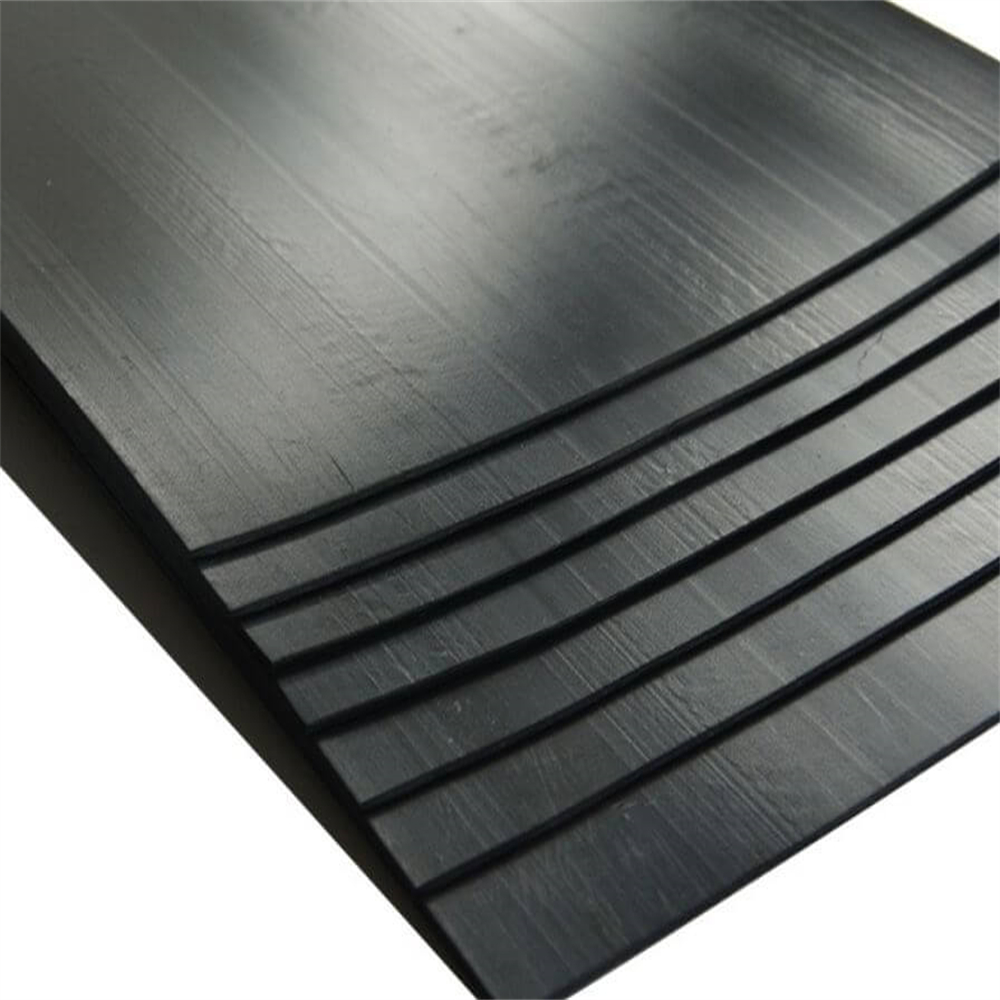

Material selection: Geomembranes are usually made of polymer materials with good anti-seepage properties such as high-density polyethylene (HDPE) or polypropylene (PP). These materials have low permeability and can effectively resist the penetration of moisture, chemicals and gases, thereby preventing leakage.

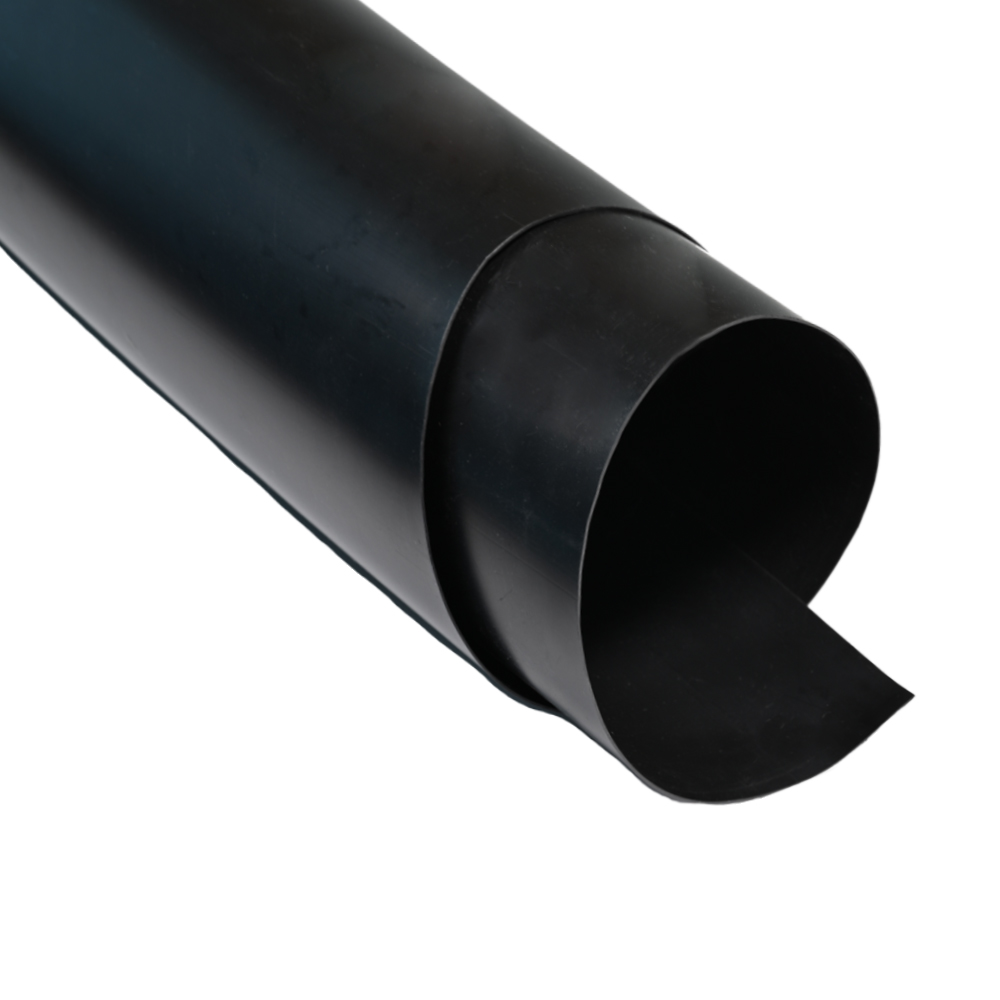

Membrane coverage: Geomembranes are generally applied to engineering surfaces that require anti-seepage in the form of continuous coverage or splicing. Cover the entire engineering area or form a sealed film layer by splicing to avoid the penetration of moisture and other media.

Edge Fixing: The edges of the geomembrane need to be fixed to prevent the intrusion of permeable media along the edge. Usually mechanical fixing, welding or burying are used to ensure the integrity of the film layer, so that it can form an effective seal with the surrounding environment.

Seam and joint treatment: During the construction process of the geomembrane, the joints need to be treated to ensure tight connection and no leakage. The commonly used methods are welding, bonding or using special joint treatment technology to ensure the continuity and sealing of the film layer.

Other auxiliary measures: In order to enhance the anti-seepage effect, it is often combined with other engineering measures. For example, cover the surface of the geomembrane with an anti-seepage layer or lay a thicker anti-seepage layer to provide an additional anti-seepage barrier; set a protective layer on the surface of the geomembrane to prevent external physical or chemical damage.

The main reason for anti-seepage in geotechnical engineering is to prevent the penetration of water, pollutants or other harmful substances through the soil, thereby protecting the stability and safety of engineering structures, and preventing pollution and damage to the environment.

Why do geotechnical engineering need anti-seepage?

Maintain the stability of the engineering structure: If water penetrates into the soil, it will cause saturation and softening of the soil, resulting in a decrease in the bearing capacity and stability of the soil. Especially for water conservancy projects such as dams, tunnels, earth embankments, embankments, etc., anti-seepage measures are necessary to prevent the penetration of water and the damage of engineering structures.

Prevention of groundwater table drop: Seepage in geotechnical engineering may cause groundwater table drop, negatively impacting the surrounding ecology and groundwater resources. Through the anti-seepage measures, the infiltration of water can be avoided, and the supply of groundwater and the suitable growth of vegetation can be maintained.

Prevent soil and water pollution: Some engineering sites (such as solid waste treatment plants, landfills, etc.) may contain harmful chemicals or sewage. If these substances seep into the soil or groundwater, they will cause environmental pollution and damage to the ecosystem. Through anti-seepage measures, the penetration of pollutants can be prevented and the quality of soil and groundwater can be protected.

Protection of buildings and infrastructure: In the construction of buildings, roads and other infrastructure, anti-seepage measures can prevent rainwater, groundwater or other moisture from penetrating into buildings or roadbeds and causing problems such as damage, cracks or settlement.

To sum up, the anti-seepage of geotechnical engineering is to protect the stability of engineering structures, prevent the decline of groundwater, prevent the pollution of soil and water bodies, and protect the integrity of buildings and infrastructure. These measures help maintain environmental sustainability and protect the safety of people and natural resources.