How to judge the quality of geomembrane?

Determining the quality of a geomembrane is a critical step in ensuring the quality of a geomembrane in civil engineering, environmental engineering, and other applications. Here are some ways to evaluate the quality of a geomembrane:

Material: First, check the raw material of the geomembrane. High-quality geomembranes usually use high-quality raw materials such as high-density polyethylene (HDPE) or ethylene vinyl acetate copolymer (EVA). Ensure that the geomembrane complies with relevant international or local standards and specifications.

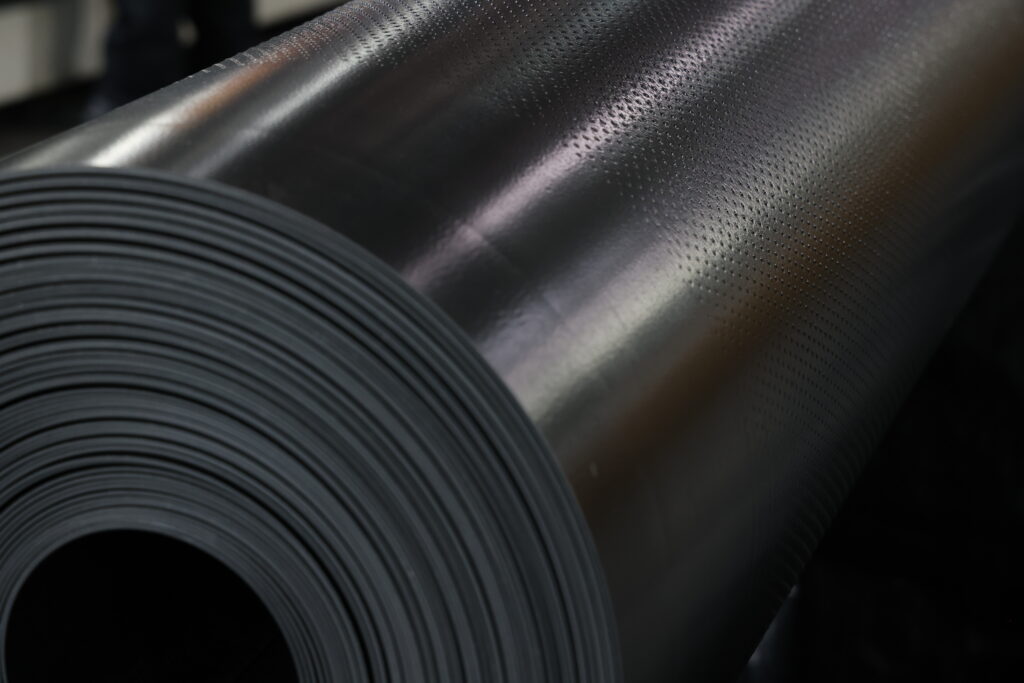

Thickness: Measure the thickness of the geomembrane to ensure it meets project specifications. Geomembrane thickness is usually expressed in millimeters or meters. Before purchasing, compare with project specifications to ensure that the thickness of the selected geomembrane is consistent with project requirements.

Strength: The geomembrane needs to be strong enough to withstand the stresses and loads involved in the project. The geomembrane is tested for tensile strength and tear strength. These data are usually found in the technical specification sheet provided by the manufacturer.

Sizes and Specifications: Make sure the geomembrane size and specifications meet the needs of the project. Check the width, length, and diameter of the roll to make sure they fit the project design.

Anti-permeability: Geomembranes are primarily used in waterproofing and anti-seepage applications. Conduct water penetration testing to confirm the impermeability of the geomembrane. This can be done through soaking, pressure testing, or other methods.

Chemical Stability: If the geomembrane will be in contact with chemicals, its resistance to chemical attack needs to be checked. Carry out relevant chemical resistance testing to ensure it will not be compromised in the project environment.

Thermal aging performance: Geomembranes need to have aging resistance to cope with ultraviolet rays and temperature changes in the natural environment. Check the geomembrane’s thermal aging performance data to ensure it has a long life.

Welding performance: If multiple geomembrane segments need to be welded together, make sure they have good welding properties to prevent leakage.

Certification and Compliance: Check that the geomembrane complies with relevant international or local standards and regulations. Some quality certification agencies such as ISO certification or ASTM international standards can also be used as a basis for evaluating geomembrane quality.

Supplier reputation: Choose a reputable supplier who typically provides high-quality geomembranes and can provide support and warranties.

How to improve the quality of geomembrane

To improve the quality of geomembranes, a series of measures need to be taken, including selecting high-quality materials, improving manufacturing processes, strictly controlling the production process, and conducting quality inspections. Here are some methods you can use to improve the quality of your geomembrane:

Choose high-quality materials: Choose high-quality raw materials, such as high-density polyethylene (HDPE) or ethylene vinyl acetate (EVA). Ensure raw materials meet relevant international or local standards and come from reliable suppliers.

Establish quality control standards: Establish clear quality control standards to ensure that each production step of the geomembrane meets specifications. This includes raw material inspection, production process control and finished product inspection.

Improved manufacturing process: Optimize the geomembrane manufacturing process to ensure that each step is carefully controlled. This may involve improving the extrusion process, hot melt process or coating process, etc.

Quality inspection and testing: Conduct a variety of quality inspections and tests, including thickness testing, tensile testing, tear strength testing, penetration resistance testing, chemical resistance testing, and thermal aging performance testing. These tests can be performed during the production process and at the finished product stage.

Employee Training: Ensure employees receive appropriate training to properly operate production equipment and perform quality control procedures. Skilled operators reduce errors and defects in the manufacturing process.

Equipment maintenance: Regular maintenance and upkeep of production equipment to ensure its normal operation. Normal maintenance of equipment helps reduce breakdowns and quality problems in production.

Quality Management System: Implement an effective quality management system such as ISO 9001 to ensure that every production step is controlled and recorded. This helps track potential issues and take corrective action.

Supplier management: Establish a stable cooperative relationship with raw material suppliers, require suppliers to provide raw materials that meet quality standards, and conduct regular supplier evaluations.

Product Tracking: Implement a product tracking system for each production batch so that if issues arise, they can be traced back to the specific production batch.

Customer feedback: Listen to customer feedback and opinions, and continuously improve product quality to meet customer needs.

How to increase the hardness of geomembrane?

The stiffness of a geomembrane is typically determined by its material and manufacturing process. If you need to increase the hardness of your geomembrane, consider the following methods:

Use high-density polyethylene (HDPE) material: HDPE is a commonly used geomembrane material with high hardness. Choosing higher density HDPE materials can increase the hardness of the geomembrane.

Increase the thickness of the geomembrane: The hardness of a geomembrane is usually directly proportional to its thickness. Increasing the thickness of a geomembrane increases its stiffness. Note, however, that increasing thickness may reduce its flexibility, so there is a trade-off between stiffness and flexibility.

Add reinforcements: Adding reinforcements, such as fiberglass or fiber mesh, to a geomembrane can increase its stiffness and tear resistance. These reinforcements make the geomembrane stronger.

Change the extrusion process: When producing geomembranes, the extrusion process, such as extrusion temperature and extrusion speed, can be adjusted to change the hardness of the geomembrane.

Use heat treatment: Some geomembranes can be heat treated to increase their hardness. Heat treatment is achieved by heating the geomembrane and allowing it to cool to change its molecular structure.

Select hardener: When manufacturing the geomembrane, hardeners, such as chemical cross-linking agents, can be added to increase its hardness. This requires proper control of hardener concentration and reaction conditions during the manufacturing process.

Optimize the molding process: Geomembranes are usually manufactured through molding processes such as extrusion or calendering. These molding processes are optimized to achieve the desired hardness and physical properties.

Comply with relevant specifications and standards: Ensure that the geomembrane is manufactured in compliance with relevant international or local standards, which often include physical property requirements such as hardness.