Polypropylene(PP) Woven Geotextiles

Category: Geotextiles

Tags: Geotextiles, PET Filament Nonwoven Geotextiles, PET Staple Fiber Needle-Punched Nonwoven Geotextiles

Wovens and non-wovens are two important geotextiles in the group of important toolboxes for soil stabilization.

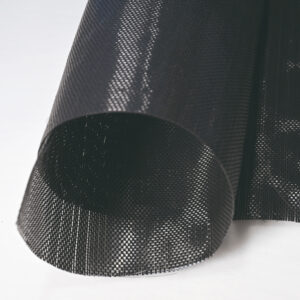

Polypropylene Woven Geotextiles are made of high-quality polypropylene fibers with great strength and low elongation to improve the drainage, stabilization, and erosion control of the soil. Tinhy’s PP Woven Geotextiles are light weighted, heavily strengthened, smaller elongated, and brilliant stabilized, which can be applied in a wide range of fields, such as pavements, railroads, infrastructure, and water conservancy projects, etc.

Tinhy’s Polypropylene Woven Geotextile is a sort of plastic geosynthetic material and made on the basis of industrial-grade looms that complect horizontal vertical threads into a firm criss-crossing net. The flat threads are generated from the extrusion, splitting, and stretching of polypropylene resin.

In many circumstances, the durability of woven geotextiles are stronger than that of nonwoven geotextiles, which are able to protect both the underneath geomembranes and soils for a much longer period. What’s more, Tinhy’s waterproof and anti-seepage system can effectively realize the reinforcement as well as subgrade stabilization of bridges, roads, airports, subways, and any other transportation or infrastructure project.

All in all, Tinhy’s Polypropylene Woven Geotextiles are designed and produced in order to enhance the separation, filtration, stabilization as well as drainage of soil conditions and functionally guard the lifespan of geomembranes. You can count on our high-quality woven geotextiles which can provide marvelous separation effect with optimal filtration and drainage functions. Our woven fabrics have higher reinforcement strengths as per the worldly recognized standard of ASTM D4595 than many stabilization products, which may eliminate potential risks during the process of your transportation or energy anti-seepage projects.

| Property | THY20-15 | THY30-20 | THY40-28 | THY50-35 | THY60-42 | THY80-56 | THY100-70 |

|---|---|---|---|---|---|---|---|

| Breaking Strength in MD KN/m | 20 | 30 | 40 | 50 | 60 | 80 | 100 |

| Breaking Strength in MD KN/m | 15 | 22 | 28 | 35 | 42 | 56 | 70 |

| Elongation Rate | 25% | ||||||

| Trapezoidal Tearing Strength, KN >= | 0.2 | 0.27 | 0.34 | 0.41 | 0.48 | 0.6 | 0.72 |

| CBR Mullen Burst Strength KN | 1.6 | 2.4 | 3.2 | 4 | 4.8 | 6 | 7.5 |

| Vertical Permeability cm/s | 10-1~10-4 | ||||||

| Sieve Size O90 (O95) (mm) | 0.07~0.50 | ||||||

| Unit Weight (g/m2) | 120 | 160 | 200 | 240 | 280 | 340 | 400 |

| Variation | ±10% | ||||||

Dimensions

| Thickness | Roll Size (Width By Length) | |

| GT150N | 1.8 mm | 6mx200m |

| GT200N | 2.3 mm | 6mx150m |

| GT250N | 2.9 mm | 6mx100m |

| GT300N | 3.2 mm | 6mx100m |

| GT350N | 3.6 mm | 6mx100m |

| GT400N | 3.9 mm | 6mx80m |

| GT450N | 4.2 mm | 6mx80m |

| GT500N | 4.4 mm | 6mx50m |

| GT600N | 4.8 mm | 6mx50m |

Packages

| Rolls (In a 40HC Container) | Quantity (In a 40HC Container) | |

| GT150N | 36 | 6mx200m |

| GT200N | 36 | 6mx150m |

| GT250N | 40 | 6mx100m |

| GT300N | 36 | 6mx100m |

| GT350N | 36 | 6mx100m |

| GT400N | 36 | 6mx80m |

| GT450N | 36 | 6mx80m |

| GT500N | 40 | 6mx50m |

| GT600N | 36 | 6mx50m |

*Our Polypropylene Woven Geotextiles are packed in woven bags