What are the standards for geomembrane product specifications?

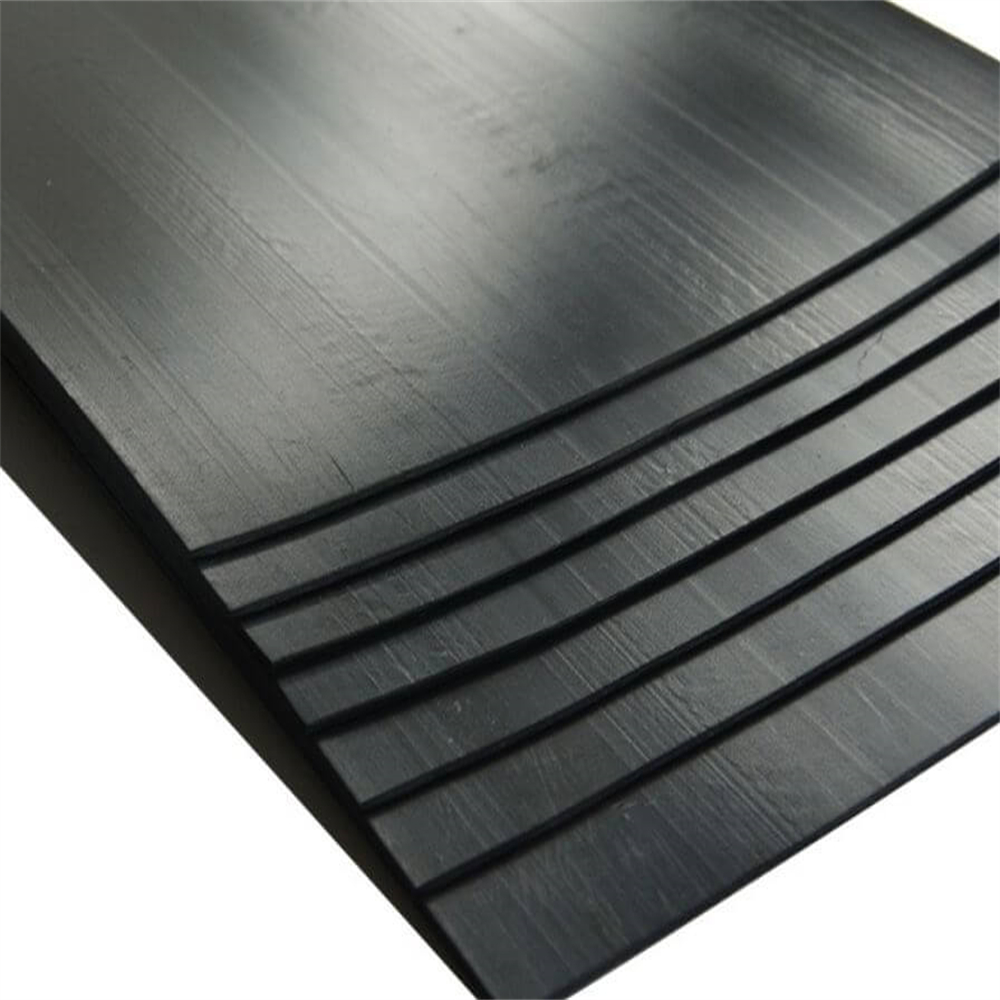

Thickness: The commonly used thickness is generally from 0.3 mm to 3 mm, and above 0.8 mm, it can also be called waterproof board. The commonly used waterproof board is EVA waterproof board, which is mainly used in tunnel engineering.

Width: Common specifications are 1 meter to 8 meters in width and 50 meters to 100 meters in length. Most manufacturers can customize it according to customer needs.

Roll length: generally 50 meters.

How to judge the quality of geomembrane products

Appearance observation: A good geomembrane should have a flat, smooth surface, no scratches or spots, uniform color and high brightness. If the surface is wavy or uneven, there may be a quality problem.

Thickness measurement: A good geomembrane should have a uniform thickness and meet the standards. By using relevant instruments for measurement, the true thickness of the geomembrane can be verified.

Strength check: A good geomembrane should have technical indicators such as high tensile strength, tear strength, puncture strength and impact resistance. The resistance of the geomembrane can be checked by applying corresponding loads, tests, etc.

Specification mark inspection: A good geomembrane should comply with national standards or industry standards, and information such as specifications, models, production dates, etc. must be marked on the product. After confirming whether the information is complete, you can know the brand, manufacturer and technical indicators of the geomembrane used in the site.

Performance testing: including hydrostatic pressure resistance test, tensile test, permeability coefficient test, etc. to check whether the performance of the geomembrane meets the requirements.

What tools are needed for geomembrane installation

Cutting tools: Cutting tools are mainly used for cutting, connecting and kneading geomembranes, common ones include cutters, connectors, hammers and scissors.

Welding machine: The welding machine is used to weld the geomembrane and connect the overlapping edges of the geomembrane.

Inflatable equipment: Inflatable equipment is used to test the welding quality and check the airtightness of the geomembrane.

Hot air welding gun: The hot air welding gun is used to weld the wider side of the geomembrane, and the lapped side is heated and connected by hot air.

Broom: The broom is used to clean the surface of the base layer before the installation of the geomembrane.

Scraper: The scraper is used to scrape off the sand stuck on the membrane cloth.

Grassroots cleaning tools: Grassroots cleaning tools include shovels, brooms, mops, etc., which are used to clean up garbage and sundries at the grassroots level.

Thermal adhesive and spray gun: The thermal adhesive is used for bonding between the film cloth and the polyethylene film, and the spray gun is used for spraying the thermal adhesive.

Prepare other necessary auxiliary tools, such as rulers, pencils, scissors, sewing kits, etc., for operations such as threading, cutting, and mending.