What is geogrid?

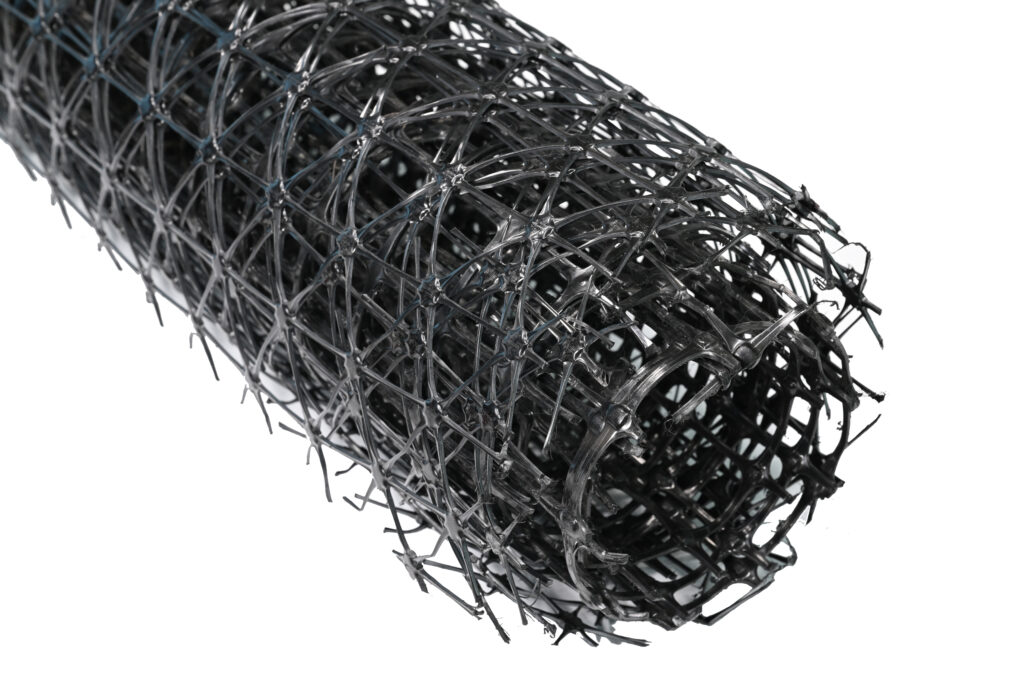

Geogrid is a geosynthetic material used in civil engineering and land stabilization. It is usually made from a high-strength polymer (such as polypropylene or polyester) or fiberglass and has a mesh-like structure. The main purpose of geogrids is to enhance the load-bearing capacity of soil, improve land stability and prevent soil erosion. Here are some of the key features and applications of geogrids:

Features:

High strength: Geogrids generally have high strength to disperse weight and resist soil deformation and settlement.

Grid-like structure: Its structure is grid-like, usually rectangular or square grid cells. This structure helps distribute loads and provides enhanced foundation support.

Lightweight: Despite its strength, the geogrid itself is typically very lightweight and easy to transport and install.

Corrosion Resistance: Geogrids are generally resistant to chemical corrosion and can be used in a variety of environmental conditions, including wet and corrosive soils.

Easy to install: It can be combined with soil or other geosynthetic materials and is usually installed by rivets, welding or tying.

Application areas:

Land reinforcement: Geogrids are used to reinforce soil, particularly in roads, railways, airport runways, parking lots and other paving projects, to reduce the risk of settlement and cracks.

Soil erosion control: It can be used in environmental protection projects such as river bank erosion prevention, shoreline protection, lake and reservoir slope stabilization, etc.

Soil retaining walls: Geogrids can also be used to construct soil retaining walls to support soil and reduce retaining wall thickness and cost.

Subgrade Support: In dirt road, railway and road construction, geogrids are used to strengthen the subgrade and provide better load-bearing capacity and stability.

Turf Enhancement: It can also be used in conjunction with turf to enhance grass stability and reduce erosion.

In summary, geogrid is a versatile geosynthetic material that can be used in various engineering projects to improve land stability, reduce soil erosion and provide strong land support. It plays an important role in the fields of civil engineering and environmental protection.

Geogrid specifications

Geogrid specifications will vary depending on the manufacturer, project needs, and application. Here are some examples of common geogrid specifications, but please note that specific specifications may vary by supplier and project:

Grid size: Geogrid grid cells can be rectangular, square, or other shapes. Typical mesh sizes can range from a few millimeters to tens of centimeters.

Mesh Aperture: This is the size of the gaps between mesh cells. The size of the holes will affect the load-bearing capacity of the grid and the penetration of the soil.

Grid Thickness: Geogrid thickness can be customized based on project needs. Common thicknesses range from a few millimeters to several millimeters.

Tensile strength: This is the tensile strength of the geogrid in the horizontal direction, usually expressed in Newtons (N) or Kilonewtons (kN).

Materials: Geogrids are typically made from polymers (such as polypropylene or polyester) or fiberglass. Gratings of different materials may have different properties.

Roll Length: Geogrids are usually sold in rolls, and the roll length can be customized according to project needs.

Color: Geogrids are typically black or light colored, but other colors are available based on project requirements.

Environmental Certifications: Some geogrids may have environmental certifications to meet the environmental requirements of a specific project.

Geogrid installation steps

Installing a geogrid requires following certain steps to ensure it functions effectively. The following are general geogrid installation steps:

Preparation:

Determine the exact specifications and dimensions of the geogrid, as well as the installation location.

Check the land surface to make sure it is smooth, clean and free of protruding or sharp objects that could damage the geogrid.

Laying the base layer:

Lay a layer of appropriate base material, such as sand or gravel, over the installation area to ensure an even foundation for the geogrid.

Laying geogrid:

Expand the geogrid and cut it according to actual needs to ensure that it covers the area required by the design.

Make sure that the grid direction of the grille is consistent with the design requirements. Normally, the grid direction should be consistent with the main force direction.

Fixed geogrid:

Secure the geogrid to the base layer using fasteners such as rivets, ground nails, or other fixtures to ensure it is firmly anchored to the ground.

Seam treatment:

If multiple pieces of geogrid need to be spliced together, ensure there is sufficient overlap at the seams and use appropriate methods (such as heat welding or nailing, etc.) to connect them together.

Cover the surface:

Cover the geogrid with additional surface material, such as soil or other cover, to protect the geogrid and provide additional support.

Compaction and fixation:

Compact the covering surface layer to ensure a good combination with the geogrid and improve the stability of the foundation.

Where necessary, use additional fasteners or fasteners to ensure the stability of the covering.

Acceptance and inspection:

Conduct final acceptance and inspection to ensure geogrid installation meets design requirements and engineering standards.