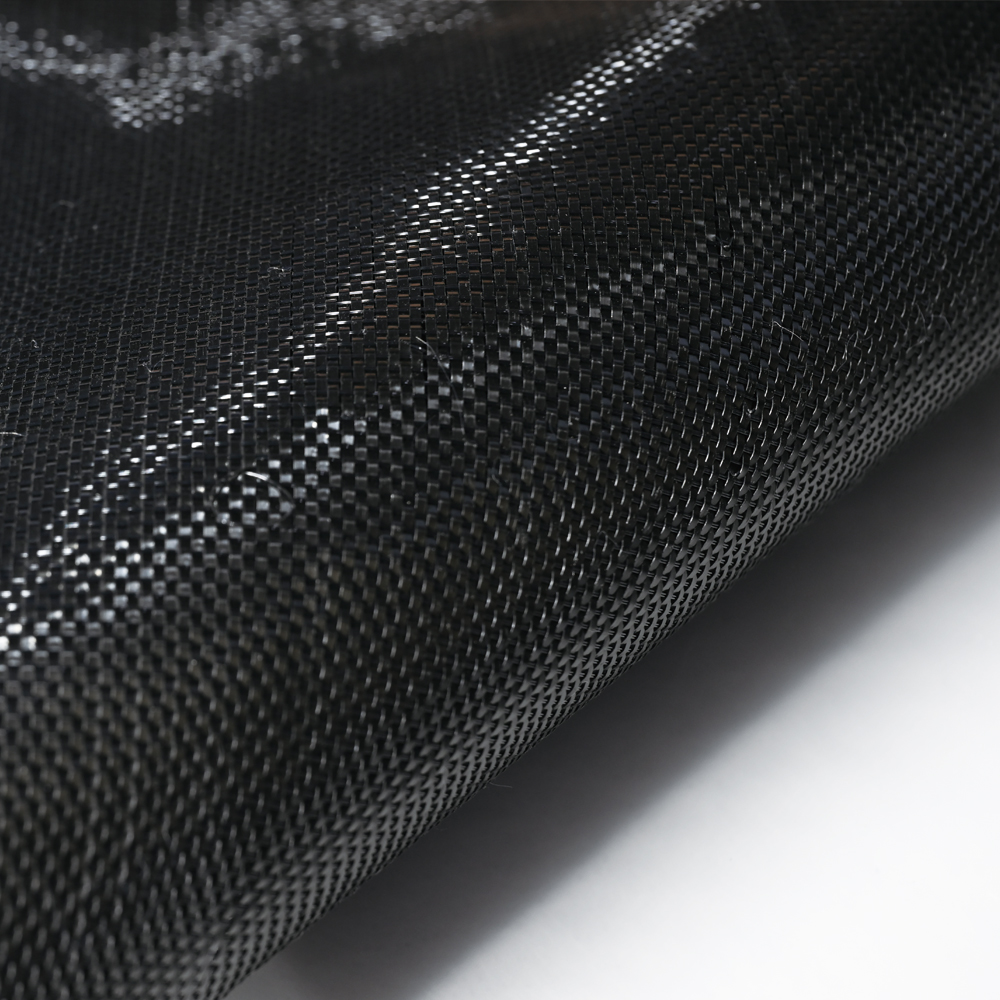

What is woven geotextile?

Woven geotextile is a material used in civil engineering and soil stabilization. Compared with traditional fabrics, it is usually mechanically woven from high-strength synthetic fibers and therefore has excellent strength and stability.

Woven geotextiles have a variety of applications in the engineering field and are commonly used in soil reinforcement, erosion resistance, soil protection, road and railway construction, etc.

Characteristics and application areas of woven geotextiles:

Soil Stabilization: Woven geotextiles can be used to enhance soil stability and reduce settlement and erosion. It is commonly used to reinforce soil slopes, river banks and road bases.

Resistant to Erosion: Woven geotextiles are used as a protective measure where water or waves are prevented from eroding the ground. It can be used for river bank protection, embankments, lake banks and shoreline protection.

Road and railway construction: Woven geotextiles can be used to strengthen road and railway foundations, improve their load-bearing capacity, reduce subgrade settlement, and extend the service life of the foundation.

Lawn and Floor Reinforcement: In places such as lawns, parking lots, sidewalks and open courtyards, woven geotextiles can be used to reinforce and stabilize the ground, reducing settlement and weed growth.

Soil Protection: In agriculture and horticulture, woven geotextiles are used for soil protection, preventing water evaporation, weed growth and soil erosion.

Filtration layer: Woven geotextiles can also be used as geofiltration layers in drainage systems, drainage channels and underground drainage projects to filter and remove excess water.

Construction Protection: In building construction, woven geotextiles are used to protect underground pipes, cables and infrastructure from damage and leakage.

Woven geotextile price

The price of woven geotextiles varies based on a variety of factors, including material type, thickness, specifications, brand, market region, and purchase quantity. The following are some of the major factors that affect the price of woven geotextiles:

Material type: Woven geotextiles are usually made of different types of synthetic fiber materials such as polypropylene, polyester, polyethylene, etc. The cost of different materials will vary, thus affecting the price.

Thickness and specifications: Woven geotextiles are available in different thicknesses and specifications. Generally, the thicker and higher the specifications, the higher the price because these specifications usually require more raw materials.

Brand: Well-known brands of woven geotextiles will generally be more expensive because they typically offer higher quality and performance guarantees. But there are also some budget brands that offer relatively cheap options.

Market region: Market prices will also vary in different regions and countries. Logistics costs, market competition and regional economic conditions will all affect prices.

Purchasing Quantity: Generally speaking, purchasing in larger quantities can result in more competitive prices. Suppliers may offer discounts or wholesale pricing, especially for large-scale engineering projects.

Special Requests: If special custom specifications, colors, or performance features are required, these additional special requests may increase the price.

Woven geotextile specifications

Specifications of woven geotextiles can vary depending on manufacturer, brand and specific project requirements. Here are some common woven geotextile specifications, but please note that these are examples only and actual specifications may vary:

Material type: Woven geotextiles are typically made from high-strength synthetic fibers such as polypropylene (PP) or polyester (PET). Material selection will depend on the specific needs of the project, such as strength and durability.

Density: Specifications for woven geotextiles usually include density, usually expressed in lines per inch (LPI). Higher density generally indicates a tighter weave, providing better strength and stability.

Weight: The grammage (g/m²) of woven geotextiles is an important specification that is often used to describe the thickness and strength of the material. Different projects may require geotextiles of different weights.

Tensile strength: The tensile strength of woven geotextiles is usually expressed in kN/m (kilonewtons/meter), which is used to evaluate its strength and stability.

Width: Woven geotextiles are usually sold in rolls, and their width can be customized as needed. Common widths include 3.0 meters, 4.0 meters, 6.0 meters, etc.

Color: Woven geotextiles are typically black or white, but other colors are available based on project needs.

UV stability: For outdoor applications, the UV stability of woven geotextiles is a key factor to ensure that it does not break down easily when exposed to sunlight.

Environmental Certifications: Some woven geotextiles may have environmental certifications to meet the environmental requirements of a specific project.

Water Permeability: The water permeability of woven geotextiles is also an important specification for drainage systems and other applications that require water permeability.