Which geomembrane is the cheapest?

The price of geomembrane depends on several factors, including material type, thickness, size, brand, market supply and demand, and geographical location. Generally speaking, HDPE (high-density polyethylene) geomembrane is usually the more economical choice, but the specific price will still vary based on the above factors.

Here are some factors that may affect geomembrane prices:

Material type: Different types of geomembranes (such as HDPE, LDPE, LLDPE, PP, etc.) have different performance characteristics and costs, so the prices will also be different.

Thickness: The thickness of a geomembrane is usually expressed in “mils” or “millimeters”. Thinner geomembranes are generally less expensive, but are also more susceptible to damage.

Size: The size and shape of the geomembrane will affect the price. Custom-sized geomembranes may be more expensive.

Brand: Geomembranes from different manufacturers may have different prices, and some well-known brands may have higher prices.

Market supply and demand: Market supply and demand will affect price fluctuations. High demand and shortages can cause prices to rise, while low demand can cause prices to fall.

Geography: Geomembrane prices may vary in different regions, depending on factors such as transportation costs, taxes, and local market competition.

Quality and Certifications: Geomembranes with specific certifications, such as products that meet relevant standards, may be more expensive.

In summary, to find the cheapest geomembrane, you can consider quotes from different suppliers and compare options of different materials, thicknesses, and sizes. Also, make sure the geomembrane you choose meets the requirements of your specific project to avoid additional costs due to quality issues. Also remember that the quality and performance of geomembranes are often crucial in engineering projects, so consider not only price but also suitability and durability when choosing.

Which geomembrane has the best quality?

In geotechnical engineering, geomembrane is a material used to control soil and water, so its quality is directly related to the stability and durability of the project. Generally speaking, the best quality geomembrane should have the following characteristics:

Chemical resistance: A high-quality geomembrane should be able to resist chemical corrosion substances in the soil, such as acids, alkalis, etc. This ensures that the geomembrane will not be damaged by chemical effects during long-term use.

Excellent tensile strength and durability: Geomembranes need to be able to withstand soil pressure and possibly mechanical stress, so it is important to have good tensile strength and durability.

Good permeability control: A high-quality geomembrane should be able to effectively control the penetration of water, thereby avoiding soil erosion and the penetration of erosive substances, and protecting the stability of the project.

Environmental protection and safety: A high-quality geomembrane should comply with relevant environmental standards and not cause pollution or harm to the surrounding environment and ecosystem.

Comply with industry standards and certifications: The best geomembranes should comply with relevant international or regional geomembrane quality standards and obtain corresponding certifications to ensure their quality and performance.

Taking the above factors into consideration, generally speaking, geomembranes made of high-density polyethylene (HDPE) tend to have better chemical resistance, tensile strength and durability. However, when selecting a geomembrane, it should also be evaluated based on the needs of the specific project to ensure that the selected geomembrane can meet the requirements of the project to the greatest extent and ensure the long-term stability and safety of the project.

What is a geomembrane?

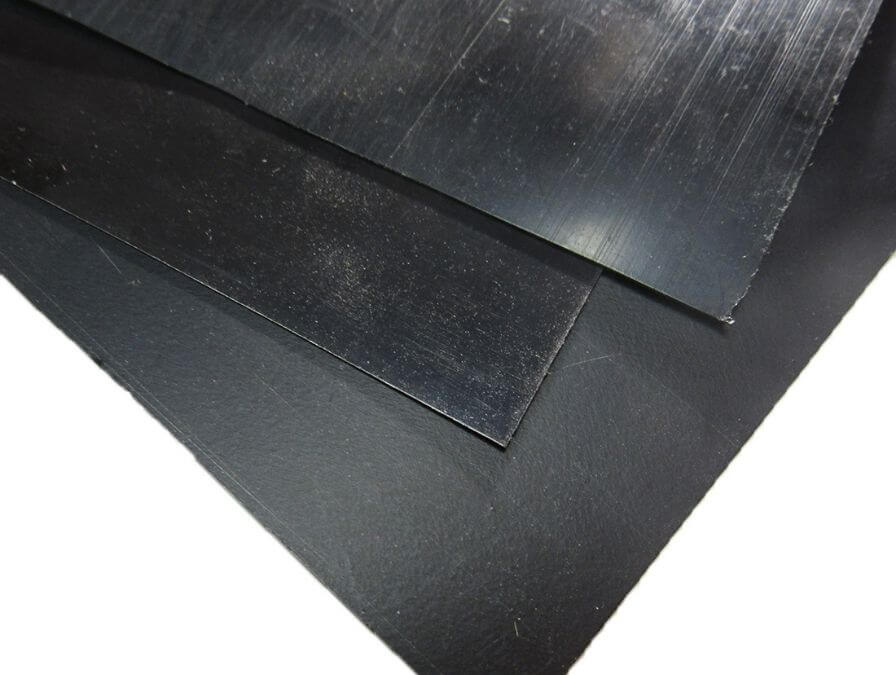

Geomembrane is a synthetic material used in geotechnical and environmental engineering, usually made of polymers. Its main function is to prevent water, gas, chemicals or other substances from penetrating into the soil to protect soil and groundwater, prevent erosion, stop leakage, etc. Geomembranes, also known as geomembranes, anti-seepage membranes, anti-seepage panels or geotextiles, have a variety of different uses and applications.

Geomembranes usually have the following characteristics and functions:

Anti-seepage performance: One of the main functions of geomembrane is to prevent moisture, chemicals or gases from penetrating from one side to the other to maintain the dryness of the soil or avoid soil contamination.

Separation: Geomembranes can be used to separate different soil layers or materials to prevent them from mixing or crossing.

Protection: Geomembrane can be used to protect underground structures, underground pipes or underground facilities to prevent external factors from adversely affecting them.

Erosion Control: Geomembranes can be used to reduce or prevent soil erosion from factors such as water flow, mud or wind erosion.

Soil reinforcement: Some geomembranes have the function of soil reinforcement, which can increase the bearing capacity of the soil.

Environmental protection: Geomembranes are used in landfills, wastewater treatment, pool and lake restoration, etc. in environmental engineering to help environmental protection and resource management.

Geomembranes are usually made of polymer materials, such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polypropylene (PP), etc. These materials have different properties and can be selected based on engineering needs. Geomembranes are usually supplied in rolls or sheets and are installed and connected according to project requirements. In geotechnical engineering, geomembrane is an important engineering material used to ensure the stability, safety and environmental protection of the project.